1. Performance test and evaluation of typical equipment

1) Refining and chemical laboratory

Test capacity: single-plate heat transfer area of 0.1-3.6m2, water flow rate of 20-300m3/h, oil flow rate of 20-100m3/h, cold-side water flow rate of 130m3/h, condensate volume of 1.46kg/s, and saturated vapor pressure over 1MPa.

(2) drilling laboratory: equipped with three sets of power systems (to adapt to the power requirements of different test equipment) test power total power of 3200kW (4353HP) maximum power of a single machine up to 2000kW (2720HP) airtight system pressure of up to 105MPa; water pressure of up to 210MPa; oil pressure of 700MPa

3) Physical and chemical strength laboratory

Conventional static tensile test, flattening test, bending test, fatigue test and analyze the material

4) Low Temperature Laboratory

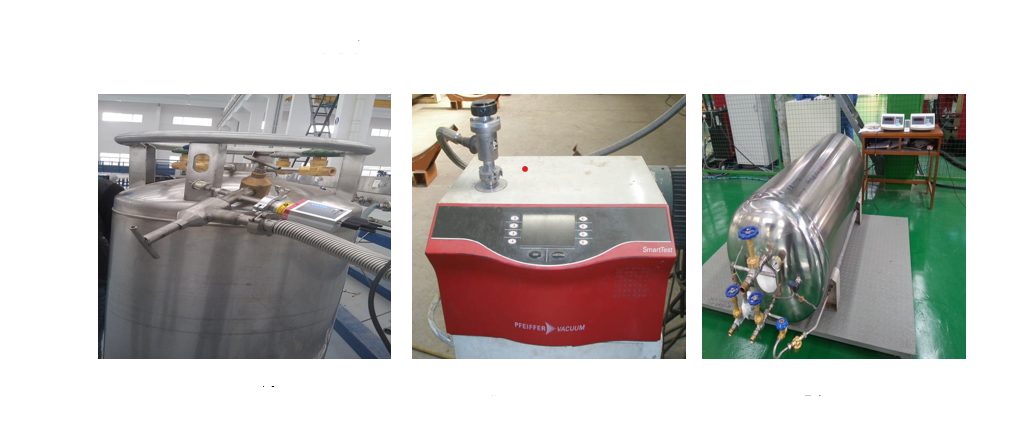

Vacuum degree test, leakage rate measurement, static evaporation rate, heat leakage measurement of vacuum adiabatic low-temperature pipes and fittings, thermal conductivity test of materials and low-temperature type test of equipments can be carried out.

2. Equipment failure analysis and safety assessment

It is a comprehensive organization specializing in testing, safety assessment, failure analysis and prevention research, repair and transformation of oilfield and petrochemical equipments. It has experts, technicians and advanced experimental equipments in the fields of materials, welding, structural strength, fracture mechanics, corrosion and protection, non-destructive testing and product inspection, etc. It has more than 30 years' experience in failure analysis and prevention research and has provided consultancy and services on failure analysis and prevention research for hundreds of enterprises and users. We have provided hundreds of enterprises and users with consulting and services on failure analysis and prevention research.

- Internal pressure fatigue test, burst test and strength analysis of containers.

- Fatigue and corrosion fatigue test of materials.

- Physical and chemical performance test, failure analysis and safety assessment of materials.

- Testing and research on the use and process performance of materials used in oil drilling and refining equipment.

- Failure analysis, safety evaluation and life assessment of equipment parts and devices.

- After the fire of large-scale petrochemical plant, pressure vessel and pressure piping inspection and safety assessment.

- Research on corrosion resistance of metallic and non-metallic materials.

- Development and popularization of new materials.

- Research on corrosion and protection of equipment in refineries and petrochemical industries.

3. Inspection of Pressure Vessels and Pressure Piping: Hidden Trouble Detection and On-Site Inspection of Special Equipment

In-use pressure vessels, in-use industrial pressure piping and boilers, pressure vessels safety

Safety valve calibration.

Periodic Inspection of Pressure Vessels in Service under Conditions of Highly Toxic Media

Inspection of pressure vessels and pressure piping at low temperatures

Gasifier and other coal chemical industry key equipment inspection and evaluation

metallurgy, power system special equipment inspection

On-line monitoring of petrochemical equipment (acoustic emission testing and surface temperature field testing, etc.)

Non-excavation inspection, safety evaluation and risk assessment of buried steel pipelines

Risk-based inspection