Air coolers are extensively used cooling equipment in petroleum refining, chemical, metallurgical, and power plant industries for cooling various process media. Compared to other cooling systems, air coolers utilize ambient air as the cooling source, delivering significant energy and water savings.

•Dry air coolers can cool media to 20°C above ambient temperature

• Wet surface air coolers and evaporative air coolers can cool media to temperatures close to the ambient wet-bulb temperature, serving as alternatives to water coolers.

LANPEC (Lanzhou LS Heavy Equipment Co., Ltd.) Air Cooler Product Range:

• Tubular Type:

Surface Evaporation Air Coolers

Advanced Surface Evaporation Air Coolers (Hybrid Air Coolers)

Dry Air Coolers

Spray-Humidification Air Coolers

• Plate Type:

Plate Wet Air Coolers

Plate Evaporative Air Coolers

Plate Dry Air Coolers

Power Plant Air Cooling (Turbine Exhaust Steam Condensation)

Closed-Cycle Water Air Cooling (Cooling Tower Replacement)

Featured Air Cooling Products

(Patents: ZL01201689.6, ZL202211290785.1, ZL202222789082.5)

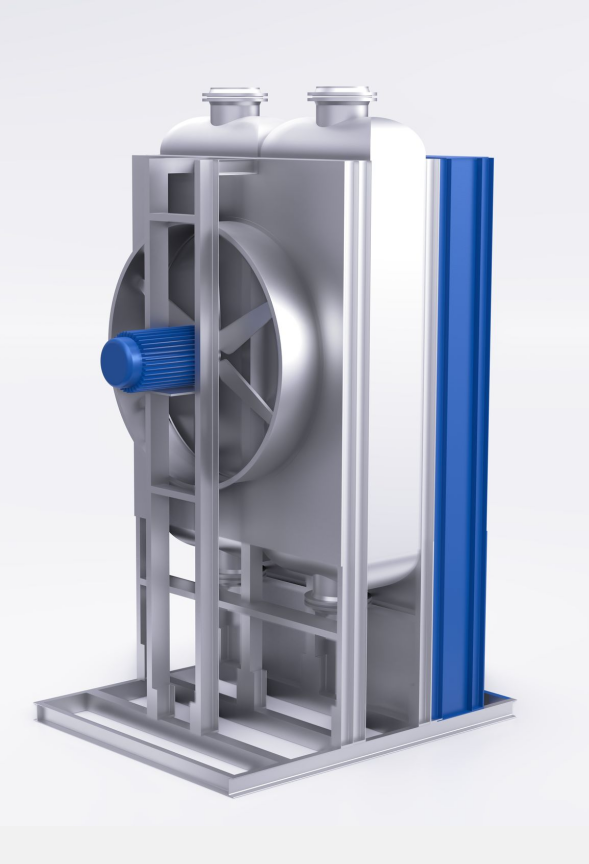

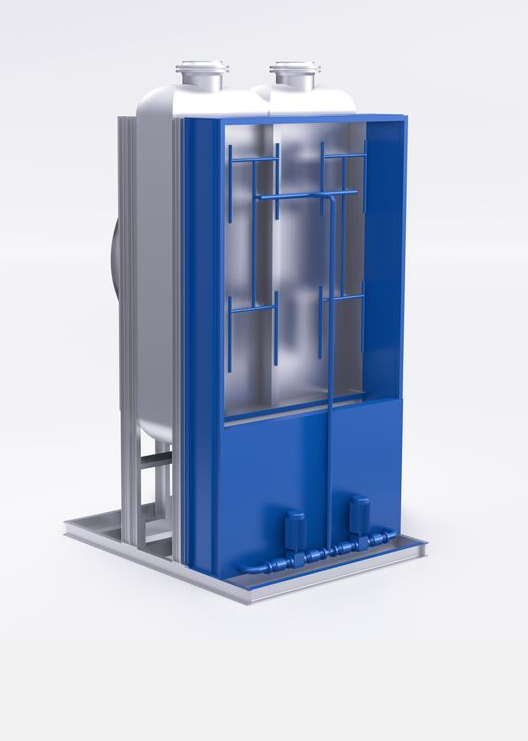

Structural Configuration:

Plate bundle, fan(s), structural frame, water tank, and spray system.

Key Features:

Design Parameters:

Design Temperature ≤ 250°C

Outlet Temperature ≤40°C (approaching ambient wet-bulb)

Design Pressure ≤2.5 MPa

Media Pressure Drop ≤65 mmH₂O

Materials 316L (gas fractionation, reforming)

2205/2507 (CDU/VDU, FCCU)

Ti (atmospheric column overhead)

Economic Advantages vs. Conventional Wet Air Coolers:

Equipment Weight 57% Reduction

Fan Power 49% Reduction

Water Consumption 67% Reduction

Operating Costs 46% Reduction

Footprint 73% Reduction

Project Portfolio (100+ systems / 500+ units deployed):

(Patents: ZL96200559.2, ZL202320391662.0, ZL202320398999.4)

Technical Features:

A high-efficiency cooling system integrating water-cooling and air-cooling principles with simultaneous heat and mass transfer. Capable of cooling process media to temperatures approaching the ambient wet-bulb temperature.

Economic Advantages:

Comparison Baseline Operating Cost Footprint

Auxiliary water cooling ≈30% -

Wet surface air cooler ≈65% ≈43%

Dry air cooler + water cooling - ≈50%

Structural Classification:

(Classification based on header configuration and heat exchanger tube geometry)

Heat Transfer Element Materials:

Aluminized carbon steel tubes, hot-dip galvanized carbon steel tubes, stainless steel tubes, copper tubes.

LANPEC's Industry Legacy:

Since the successful development of surface evaporation air coolers in the early 1990s, continuous design refinement has delivered 300+ systems and over 3,000 units to the industry. Proven applications include:

Structural Configuration:

Manifold header with serpentine tube arrangement.

Heat Transfer Element Materials:

Major Project Portfolio:

LANPEC's advanced surface evaporation air coolers have been extensively deployed across China's petrochemical complexes, with installations in: