LANPEC's primary welded plate heat exchanger products include:

Product Features:

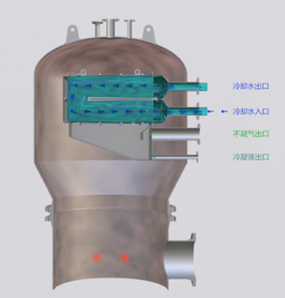

Engineered for high-pressure operation with exceptional structural stability, this compact, highly integrated unit installs inside distillation/concentration columns to perform:

in a single energy-integrated multistage coupling system.

Suitable for:

Key Specifications:

Max. Temperature >200°C

Max. ΔP Across Streams >1.5 MPa

Pressure Drop ≤0.05 kPa (ultra-low per stream)

Max. In-Tower Area 12,000 m² (modular assembly)

Material Options:

300-series SS • 254SMO • Hastelloy C276 • 2205/2507 Duplex • Ti

Competitive Advantages:

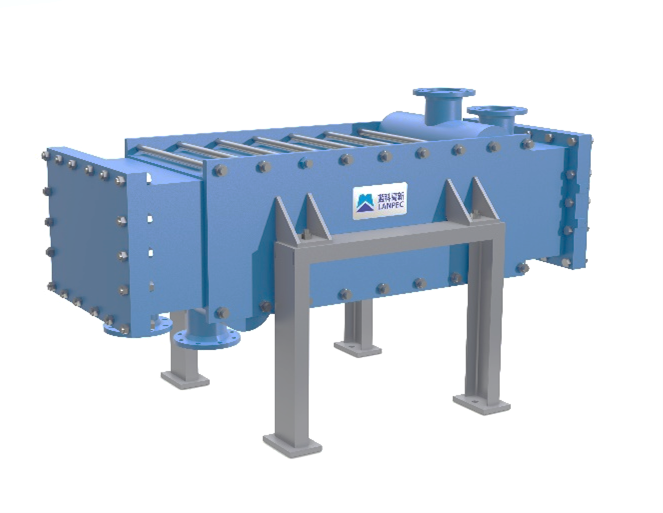

Product Features:

As a signature variant of LANPEC's HA-series welded plate exchangers, this fully welded unit delivers cost-effective thermal solutions for:

Technical Advantages:

Key Specifications:

Max. Temperature 500°C

Max. Pressure 5.0 MPa

Corrosion Resistance CRAs per NACE MR0175

Material Options:

300-series SS • 254SMO • Hastelloy C276 • 2205/2507 Duplex • Ti

2. HA Cover-Plate Welded Plate Heat Exchanger

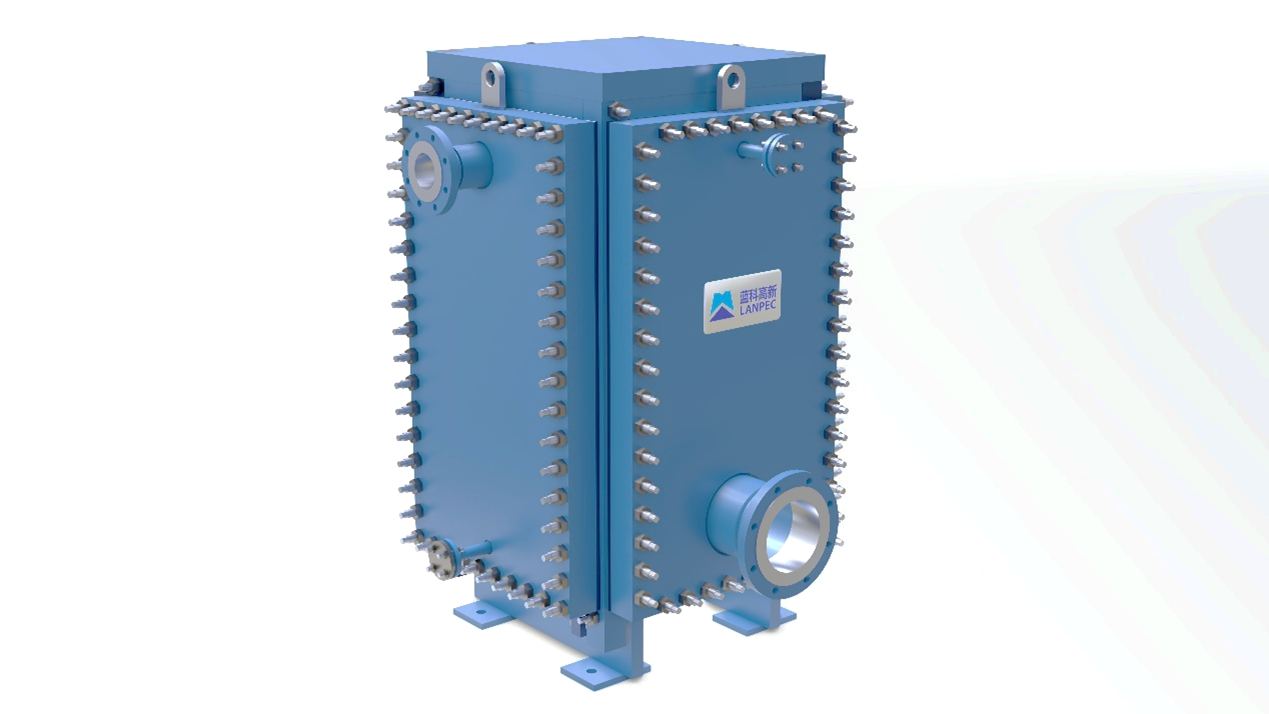

Product Features:

As a specialized HA-series variant, this Removable-Cover Fully Welded Plate Heat Exchanger excels in fouling-prone services:

Technical Advantages:

Maintenance-Optimized Design:

▶ Removable cover assembly

▶ Full access to plate pack

▶ Mechanical cleaning capability

Key Specifications:

Max. Temperature 500°C

Max. Pressure 5.0 MPa (gasket-free)

Material Options:

300-series SS • 254SMO • Hastelloy® C276 (UNS N10276) • 2205/2507 Duplex • Ti

Maintenance Superiority:

Cover removal enables direct mechanical cleaning

High-pressure jet/sponge ball cleaning compatible

Visible connection welds for leak testing (ASME Sec. V)

Localized weld repair capability without full disassembly

Product Features:

The HC Detachable Cassette-Type Plate Heat Exchanger serves critical applications across:

Robust Construction:

▶ Tendency for adhesion

▶ Fouling susceptibility

▶ Scaling propensity

Maintenance-Optimized Design:

Periodically unbolting the sealed cover plate enables:

▶ Full internal mechanical cleaning access

▶ Visual inspection of weld joints

Key Specifications:

Max. Temperature 350°C

Max. Pressure 3.5 MPa (gasket-free)

Material Options:

300-series SS • 254SMO • Hastelloy® C276 • 2205/2507 Duplex • Ti • Zr

Maintenance Superiority:

Cassette extraction for offline cleaning

High-pressure water/chemical cleaning compatibility

Direct visual weld examination (ASME Sec. V Art. 9)

Localized weld repairs without full disassembly

Titanium Heat Exchangers

Corrosion Resistance:

As a non-ferrous metal, titanium delivers exceptional performance in chloride-containing media:

Primary Applications:

Zirconium Heat Exchangers

Corrosion Resistance:

This rare metal resists extreme corrosion environments including:

Economic Advantages:

Primary Applications:

Technical Specifications:

Max. Temperature 350°C (Zirconium)

Max. Pressure 2.5 MPa

Material Options Hastelloy® C276 • Ti • Zr