LANPEC offers the following main plate-and-shell heat exchanger products:

Reforming Mixed Feed/Effluent Plate-and-Shell Heat Exchanger

Product Features:

The Mixed Feed/Effluent Plate-and-Shell Heat Exchanger excels in heat recovery under high-temperature, high-pressure conditions. It combines the high-efficiency heat transfer of welded plate heat exchangers with the high-temperature/pressure resistance of shell-and-tube exchangers.

Key advantages include:

• Superior heat transfer efficiency

• Low hot end approach temperature

• Reduced pressure drop

• Compact footprint

• Lower total investment

This technology enables:

• Efficient process heat recovery

• Reduced heater load

• Lower plant energy consumption

• Enhanced energy savings

Key Specifications:

Design Temperature . 300°C - 550°C (Max: 650°C)

Design Pressure. Max 35 MPa (Plate bundle: 5.0 MPa)

Heat Transfer Area 500 - 13,000 m²

Min. Approach Temp.1 - 3°C

Pressure Drop ≤80 kPa

Competitive Advantages:

Primary Applications:

As feed/effluent exchangers in:

Catalytic reforming units

Aromatics disproportionation & isomerization units

Reforming pre-hydrotreating units

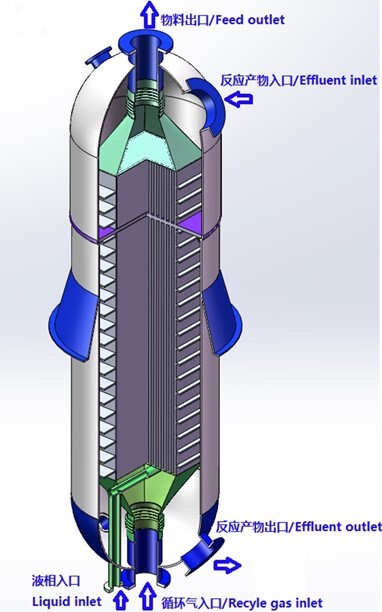

Coal-to-Oil Circulating Heat Exchange Separator

Product Features:

The Circulating Heat Exchange Separator is deployed in Fischer-Tropsch synthesis units of coal-to-liquid plants. It cools hydrocarbon vapor-liquid mixtures from reactors through heat exchange with circulating gas, simultaneously achieving phase separation. The separated liquid phase (heavy oil) is heated and fed to strippers, while the vapor phase flows to overhead air coolers. This innovative system integrates:

High-efficiency heat transfer of plate-and-shell technology

Precision separation capabilities

Dedicated anti-clogging plate design

Key advantages include:

Dual-function integration (heat transfer + separation)

Exceptional thermal efficiency

Superior separation accuracy

Compact footprint with simplified piping

Patented design recognized with China's 2020 National Science and Technology Progress Award (First Prize) for its role in the 4-million-ton annual coal indirect liquefaction project

Key Specifications:

Max. Design Temp. 480°C

Max. Design Press. 35 MPa (Plate bundle: 5.0 MPa)

Heat Transfer Area 200 - 10,000 m²

Pressure Drop ≤80 kPa

Vapor-Liq. Sep. Eff. >99%

Competitive Advantages:

• Space-saving integrated functionality

• High thermal efficiency

• Exceptional fouling resistance

• Intergranular & acid corrosion resistance

• Low operational costs

• Proven reliability in industrial applications

Methanol Plate-and-Shell Gas-Gas Heat Exchanger

Product Features:

Deployed in methanol and ethylene glycol plants, Large Plate-and-Shell Gas-Gas Heat Exchangers significantly reduce energy consumption by recovering waste heat from outlet gases to preheat inlet gases. Key advantages include:

Superior heat transfer efficiency

Low hot end approach temperature

Minimal pressure drop

Compact footprint

Lower capital expenditure

Key Specifications:

Max. Design Temp. 400°C

Max. Design Press. 35 MPa (Plate bundle: 5.0 MPa)

Heat Transfer Area 500 - 8,000 m²

Pressure Drop ≤80 kPa

Competitive Advantages:

High-efficiency heat recovery

Reduced operational costs

Optimized pressure loss

Custom-engineered performance

Comprehensive lifecycle support

Benchmark Analysis (600 kta Methanol Plant):

Shell-and-tube gas-gas heat exchangers exhibit approximately 2.3× greater weight than equivalent plate-and-shell units. The competitive advantage of plate-and-shell technology amplifies significantly with increasing plant scale, driving industry-wide adoption for:

Greenfield projects

Capacity revamp initiatives

This displacement trend positions plate-and-shell heat exchangers as the preferred replacement for conventional shell-and-tube designs in modern process facilities.

Primary Applications:

As gas-gas heat exchangers between reactor inlet/outlet streams in:

Methanol synthesis units

Ethylene glycol production facilities

Large Plate-and-Shell Overhead Condenser

Product Features:

The Large Plate-and-Shell Overhead Condenser features a safety-conforming rotating shell housing high-efficiency variable-pitch plate-type heat transfer elements. Its optimized design includes:

This innovative configuration integrates condensers for pre-flash and flash towers into a single unit, achieving efficient condensation/cooling of high-volume vapor streams under vacuum operation.

Key Specifications:

Max. Design Temperature 400°C

Max. Design Pressure 4 MPa

Heat Transfer Area 500 - 10,000 m²

Hot Side Pressure Drop ≤1 kPa (ultra-low)

Material Options:

300-series SS • 2205 Duplex • 2507 Super Duplex • 254SMo • Ti

Competitive Advantages:

Primary Applications:

Overhead condensation/cooling in:

Circular Plate-and-Shell Heat Exchanger

Product Features:

The Circular Plate-and-Shell Heat Exchanger (PSHE) revolutionizes thermal transfer by replacing traditional tube bundles with plasma arc-welded corrugated plate assemblies housed within a rotary-formed cylindrical shell. Two fluid streams exchange heat through separate plate-side and shell-side channels, achieving highly turbulent flow across corrugated plates for exceptional heat transfer efficiency.

Structural Advantages:

Optimized Safety: Monolithic circular plate bundle ensures uniform stress distribution with superior pressure/thermal shock resistance (ASME Sec. VIII Div. 2 compliant)

Pressure Boundary Integrity: Gasket-free construction eliminates leakage risks

Performance Excellence:

Extreme Service Capability:

Material Versatility:

Plates 300-series SS • 254SMO • Hastelloy C276 • 2205/2507 Duplex • Ti • Zr

Shell Carbon steel • Composite-lined

Operational Flexibility:

Technical Specifications:

Max. Temperature 900°C (special alloys)

Max. Pressure 20.0 MPa

Corrosion-Resistant Materials:

Heat transfer elements are available in high-grade alloys including:

300-series Stainless Steel (304/316L per ASTM A240)

254SMO® (UNS S31254)

Hastelloy® C276 (UNS N10276)

Duplex Steels (2205: UNS S32205, 2507: UNS S32750)

Titanium (Gr.1/2 per ASME SB-265)