Technical Background:

Coal indirect liquefaction technology is one of the core technologies for coal-to-liquid (CTL) production, long monopolized by South Africa's Sasol. To break this foreign technological monopoly, China initiated its first Circulating Heat-Exchange Separator project—a solution fundamentally distinct from foreign approaches.

Development Process:

In 2014, LANPEC dedicated efforts to address critical technical challenges, equipment assurance, and project coordination for the *4-million-tons-per-annum Coal Indirect Liquefaction Integrated Technology Development and Industrialization Project*. With no existing circulating heat-exchange separator technology globally, LANPEC established a task force to develop China’s first domestically produced unit, integrating heat exchange and high-temperature vapor-liquid separation into a single system.

Technical Breakthrough:

The team overcame multiple world-class challenges—including anti-clogging high-efficiency heat transfer/separation and structural stability of ultra-large plate bundles—achieving successful industrial application at the million-ton-scale coal-to-liquid production level.

Application Results:

Exemplified in the Fischer-Tropsch synthesis unit of Ningxia Coal Industry Co., Ltd. (a subsidiary of China Energy Group), the domestically developed separator achieves:

Technical Significance:

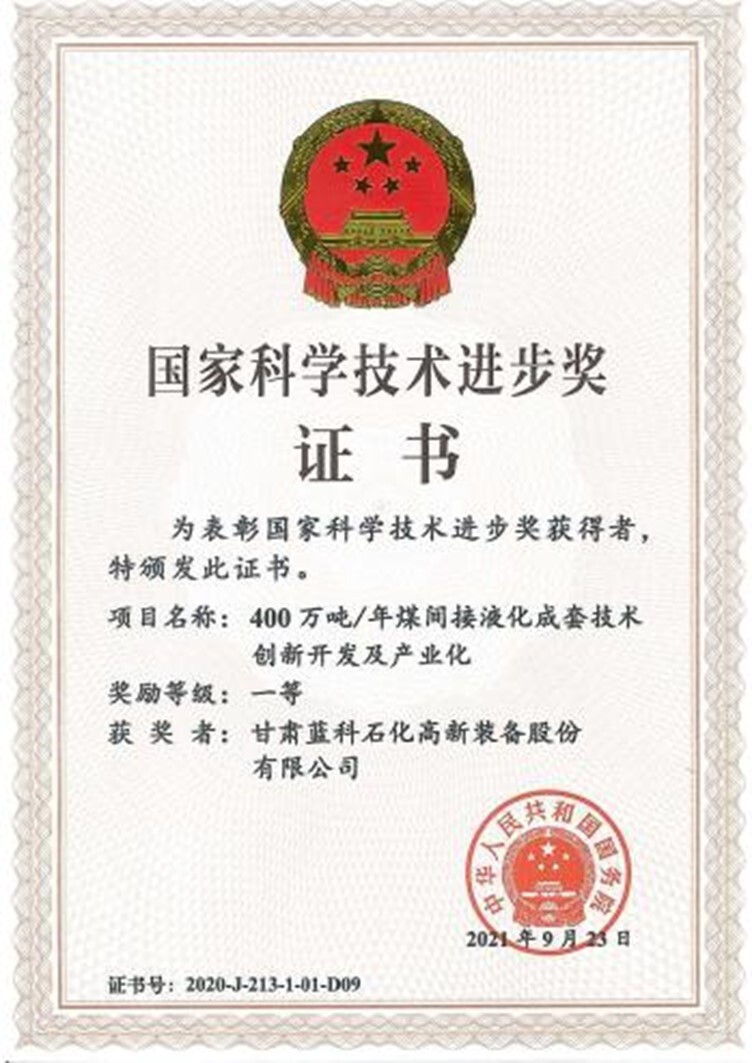

LANPEC’s separator successfully broke foreign monopolies, establishing a replicable integrated heat-exchange and separation technology for Fischer-Tropsch units. This advancement significantly contributes to mitigating China’s petroleum shortages, reducing external dependence, countering international supply restrictions, and enhancing national energy security. In November 2021, the 4-million-tons-per-annum CTL project won China’s 2020 State Science and Technology Progress Award (First Class)—the nation’s highest scientific honor—with LANPEC as a key contributor.